In today's competitive industrial sector, the ability to transform data into effective decisions is essential to achieve operational excellence and maximize profitability. MES systems have established themselves as fundamental tools to achieve this goal, providing...

The difference between having or not having a MES System in your ceramic factory

Implementing an MES (Manufacturing Execution System) in a ceramics factory can transform workflow and efficiency compared to not having one. Here's the difference in some key aspects: 1. Production control and visibilityWithMES: provides a real-time view of the entire...

Advantages of the MES Control Ceramics system

The MES Control Ceramics system is specifically designed to optimize production in the ceramics industry. Thanks to its advanced technology and focus on automation, it not only improves operational efficiency, but also provides valuable tools for informed decision...

100% paperless: driving efficiency in the ceramics industry

Digitization is a key driver of efficiency and competitiveness in the ceramics industry. Adopting 100% paperless factory management not only optimizes processes, but also contributes to sustainability and reduced operating costs. 100% paperless keys Improved...

Control Ceramics, much more than a MES System

The first half of 2024 has been a success thanks to you. The launches of Ceramics Energy Control y Control Ceramics CMMS have been decisive to continue advancing in the offer of digitalization systems that cover all the needs of the ceramic industry, as well as those...

Monitor the energy consumption of your ceramic factory

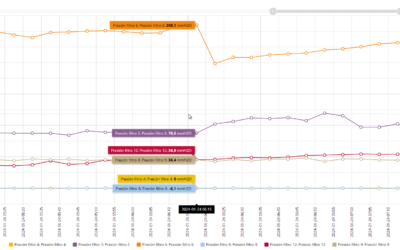

Still not monitoring the energy consumption of your ceramic factory? Direct influence on production Efficiency in ceramics production is closely linked to energy consumption. A monitoring system allows immediate detection and troubleshooting, reducing downtime and...

The only MES System specifically for the ceramic sector

Achieve digital transformation and industry 4.0 for your ceramics factory Each sector has its own idiosyncrasies, and the ceramic sector is no exception. With more than 20 years of experience working intensively in this field, we have acquired a deep knowledge of its...

A connected worker benefits your factory

Digitalization is transforming factories, introducing changes in processes and optimizing production. One of the key figures in this transformation is the "connected worker". But how can it drive your company's growth? Access to real-time information Connected workers...

Optimize the maintenance of your ceramic plant with a CMMS

What is a CMMS? It is an advanced solution designed to optimize maintenance management in ceramic plants. This comprehensive tool streamlines and automates maintenance and overhaul operations, offering greater efficiency and control in the management of your assets....

Ceramics Energy Control for Exagres

Exagres is a benchmark in the ceramic extrusion industry, and has recently expanded its MES Control Ceramics system at its main production plant with the integration of the Energy module. This incorporation makes it possible to record the energy values of the...

Artificial vision system at Living Ceramics

The installation of a machine vision system at Living Ceramics' grinding plant has meant a step forward in its operations, as well as a significant improvement in efficiency and quality. The main objective of this project was to implement an artificial vision solution...

Integrated differential pressures for Marazzi

The project focuses on the process of incorporating the differential pressures of the suction filters into the Control Ceramics web application. It involves several tasks, such as the assembly of two new communication panels for one of the plants and the creation of...